Effective Maintenance of Direct Injection Systems

Author: Dan Cuschieri Date Posted:24 May 2024

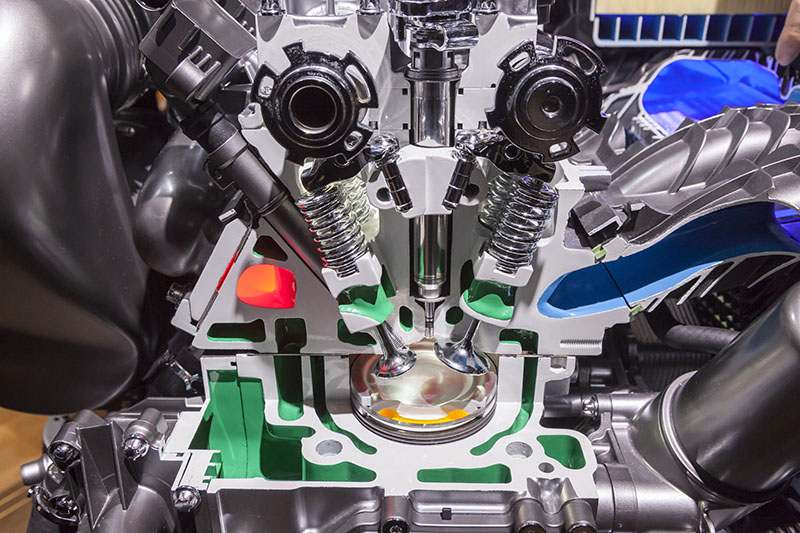

Introduction to Direct Injection Engines

Modern engines increasingly rely on direct injection systems to enhance performance and fuel efficiency. By injecting fuel directly into the combustion chamber, these systems allow for precise control over the fuel-air mixture, resulting in increased power output and lower emissions. However, the intricacies of direct injection systems necessitate regular maintenance to maintain optimal functionality.

Challenges with GDI Engines

Gasoline Direct Injection (GDI) engines deliver remarkable performance and efficiency when new, but their benefits can diminish over time. Due to tighter mechanical tolerances and higher soot and particulate production, GDI engines are prone to contamination as they age. Common issues reported by owners include illuminated engine management lights, decreased power, and excessive exhaust emissions, which can lead to roadworthiness test failures. Contaminants often bake onto the injector tip, blocking the fine holes and altering the spray pattern, which engine management systems can only compensate for to a limited extent.

Comprehensive GDI System Cleaning

Addressing contamination in GDI engines is complex. JLM Lubricants has developed the JLM GDI Injector Cleaner to tackle these challenges effectively. This product not only cleans existing deposits on injectors but also prevents future buildup, ensuring that injection systems maintain peak efficiency. Tests conducted at the Millbrook Proving Ground in Bedfordshire, England, demonstrated that JLM's GDI Injector Cleaner outperforms other detergents by providing faster and more thorough clean-up. Additionally, it reduces fuel consumption by over 4% and lowers particulate emissions, underscoring its environmental benefits.

Benefits of JLM's GDI Injector Cleaner

- Suitable for all Gasoline Direct Injection Systems, including GDI, FSI, TSI, TFSI, CGI, and SIGI engine types.

- Ensures excellent nozzle cleanliness and cleans the inside of GDI injectors.

- Reduces emissions of particulates, NOx, and CO2.

- Meets Euro 6/VI+ exhaust emission standards.

Conclusion

Proper maintenance of GDI engines is essential to sustain their performance and efficiency. The JLM GDI Injector Cleaner, combined with JLM's Engine Oil Flush and Air Intake Cleaner, offers a robust solution for cleaning and preventing buildup in direct injection systems. Regular use of these products helps GDI engines run smoothly, reducing emissions and improving fuel efficiency. By staying diligent with maintenance, car owners can prolong the life of their engines and fully benefit from GDI technology.

For all trade enquiries and to order please contact us on sales@martiniracing.com.au